What is traceability?

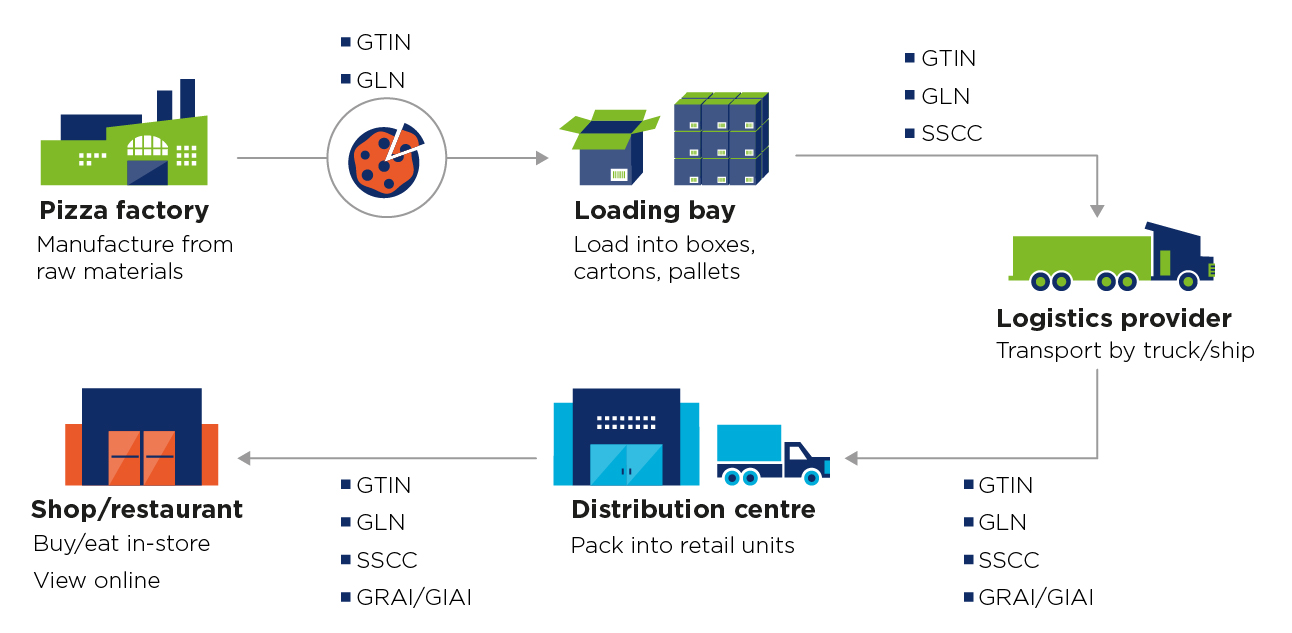

Traceability enables products to be made visible across the supply chain, building fundamental blocks within quality, risk and other related management systems.

How traceability standards work

The GS1 Traceability Standard defines minimum traceability requirements within business processes to achieve full chain traceability, independent of any technology. It is a meta-standard composed of other GS1 standards – such as barcodes, EPCIS and GS1 EDI.

This standard builds a framework for end-to-end traceability systems, linking the flow of information to physical products. This enables all trading partners involved in a supply chain – manufacturers, transporters, ware houses, retailers – to have the required traceability information in an event of a recall.

The GS1 Global Traceability Standard is the basis of the GS1 Global Traceability Checklist, a document used to conduct gap analysis for critical points in traceability systems. Companies can verify the quality and integrity of their existing traceability processes using this Checklist or consult our traceability experts for an assessment.

Traceability data

There is so much data being exchanged between trading partners. However, there are 3 categories of data being shared with examples being relevant for traceability purposes as follows:

-

Master data – data which is permanent or relatively constant over time and provides descriptive attributes of products, parties and physical locations (e.g. name of company, contact details, address)

-

Transaction data – data created during the real-world flow of products, captured when events such as loading or unloading occur in trade transactions or a business process in a business arrangement (e.g. time of production, best before date)

-

Visibility event data – data detailing physical activity of products and other assets answering the “What, When, Where and Why” at real-time (e.g. temperature log)